Maximizing Hydrogen’s Purity and Efficiency

Liquid hydrogen (LH₂) provides superior energy density and purity for advanced clean energy applications. GenH2 Liquefaction solutions convert gaseous hydrogen into ultra-pure liquid hydrogen using advanced cryogenic technology, maximizing storage efficiency, safety, and performance.

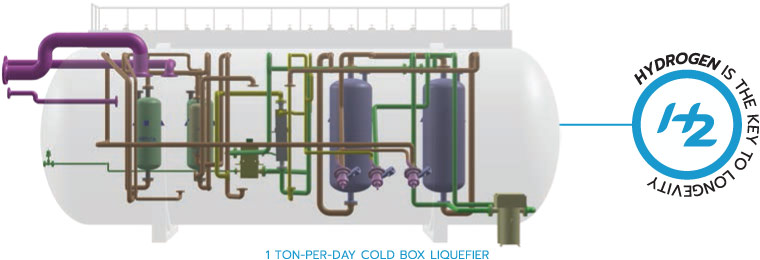

Light-Scale Hydrogen Liquefaction Technology

GenH2’s light-scale liquefaction systems produce ultra-high purity liquid hydrogen from a variety of gaseous hydrogen sources, including electrolyzers, storage tanks, and reformers.

Inspired by NASA-pioneered technology, GenH2 systems deliver high efficiency, optimized capacity, and a compact footprint. The modular design enables scalable deployment without requiring liquid nitrogen pre-cooling.

Available system capacities range from small-scale (2–20 kg/day), medium-scale (50–100 kg/day), to industrial-scale (1,000 kg/day).

- Ultra-High Purity Liquid Hydrogen: Liquefaction removes impurities, delivering ultra-high-purity LH₂ with consistent performance.

- Closed-Loop, Helium-Cooled System: Helium-based cryogenic cooling provides precise control and reliable operation.

- Dry System – No LN₂ Pre-Cooling Required: Eliminates liquid nitrogen pre-cooling, reducing costs and system complexity.

- Modular, Scalable Architecture: Light-scale modules enable fast deployment and simple capacity expansion.

- Optimized Size, Capacity, and Efficiency: High efficiency and throughput in a compact, space-saving footprint.

Compact, Scalable Clean Energy

GenH2 Liquefaction systems are designed for flexible deployment and rapid scalability. The compact footprint supports on-site and remote installations where traditional liquefiers are not viable.

Smaller systems may be portable and integrate seamlessly with renewable energy sources such as solar, wind, and hydropower. Reduced lead times and capital requirements enable faster hydrogen adoption across transportation, aviation, shipping, and off-grid power applications.

GenH2 Liquefaction units can operate independently or as part of a complete hydrogen ecosystem, with select models capable of reliquefying captured hydrogen boil-off to improve overall system efficiency.

The Liquefaction Process

- Gaseous Hydrogen Input: Hydrogen is supplied from electrolyzers, storage tanks, or reformers. Source purity determines final LH₂ purity.

- Pre-Cooling: Hydrogen is pre-cooled using helium-based cryo-refrigeration, with optional liquid nitrogen to increase liquefaction speed.

- Liquefaction: Hydrogen is cryogenically cooled and condensed into liquid form using a dry, closed-loop helium system, producing ultra-pure LH₂ with high efficiency and reduced operating costs.

Download our Solution Brief to learn more about the process and benefits of hydrogen liquefaction!

- Clean

- Efficient

- Reliable

- Flexible

- Compact