Unlocking the Power of Liquid Hydrogen

Read Time: 0 minutes

Greg Gosnell, GenH2, USA, discusses why zero-loss liquid hydrogen technology will be key to large scale mobility fueling.

As hydrogen technologies evolve, liquid hydrogen (LH₂) is emerging as a powerful force in energy transition. While hydrogen has long been recognized as a versatile, zero-emission energy carrier, confusion still lingers – especially around the comparative advantages of LH₂ vs gaseous hydrogen (GH₂). Yet, the verdict from industry experts, engineers, and infrastructure developers is becoming increasingly apparent: LH₂ is the superior choice, particularly for mobility and large scale applications.

An example of a zero-loss LH₂ system, including refrigerated controlled storage for a hydrogen refueling station.

With hydrogen poised to play a central role in decarbonizing sectors such as heavy-duty transport, bus mass transit, aviation, maritime, and backup power storage, scaling efficiently and safely is no longer optional, it is essential. To unlock hydrogen’s full potential and accelerate the transition to net zero emissions, two strategic priorities must be addressed:

- Broad recognition and adoption of LH₂ – not GH₂ – as the future of large scale mobility fueling.

- Deployment of technologies that eliminate every mode of LH₂ loss during transfer and storage.

Why LH₂ wins: the superior hydrogen-state

While GH₂ and LH₂ each play essential roles in the developing hydrogen economy, LH₂ delivers critical advantages for high-efficiency, high-density applications:

Higher energy density, smaller footprint

LH₂ is approximately 800 times denser than its gaseous counterpart at atmospheric pressure and up to eight times denser than highly compressed GH₂. This translates into a dramatically smaller storage and delivery footprint – critical for fueling stations in dense urban environments, space-constrained industrial sites, and mobile refueling platforms.

Lower pressure, greater safety

Unlike GH₂, which must be compressed to pressures up to 700 bar (10 000 psi) for storage and transport, LH₂ is stored at cryogenic temperatures (~-253°C) and very low pressure, reducing risks associated with high-pressure systems. This makes LH₂ infrastructure inherently safer to operate and maintain.

Superior logistics and distribution efficiency

One LH₂ tanker can deliver the same amount of hydrogen as up to eight GH₂ trailers, vastly improving transport economics. In addition, LH₂ fueling stations can dispense several tonnes per day through a single pump – something that would require multiple GH₂ compressors and complex systems, increasing both capital and operational costs.

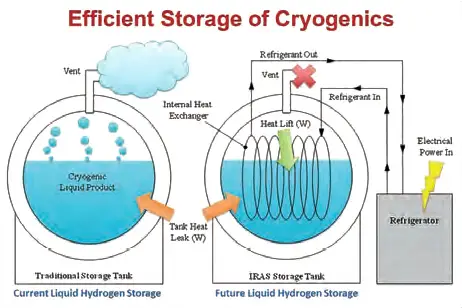

NASA GODU for LH₂ study – diagram with simplified comparison of a traditional storage tank and an IRAS System.

Flexibility for futureproofing

When hydrogen refueling stations use GH₂ as the storage medium, the only option is to fuel GH₂ onboard tanks. However, when using LH₂ as the storage medium, the operator and end-user can employ either GH₂ or LH₂ onboard tanks.

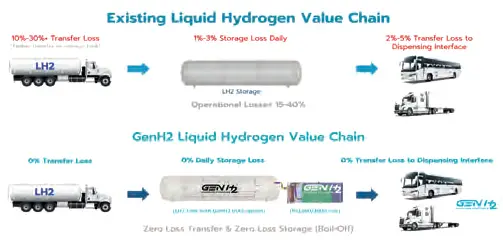

The challenge: preventing hydrogen loss

Despite its promise, hydrogen’s small molecular size and volatile properties present formidable engineering challenges, especially for LH₂. Hydrogen loss during transfer, storage, and dispensing is a significant barrier, with real-world losses in some systems exceeding 40%. These losses are not just economic – they represent wasted clean energy and a setback in emissions reduction goals.

Where LH₂ losses occur

Bulk storage tank filling

During offloading from a tanker into a bulk storage tank, cryogenic LH₂ meets a warm bulk storage tank and warmer, saturated LH₂ remaining in the tank. When this occurs, the LH₂ vaporizes, causing pressure to build up in the receiving tank, which forces operators to vent the GH₂ vapor. This process alone can result in a hydrogen loss of up to 30% per transfill.

Normal evaporation rate (NER)

Even highly insulated cryogenic tanks allow some heat to seep in, resulting in a daily loss of 1 – 3% through boil-off. Over time, this becomes a significant operational cost.

Dispensing losses

When warmer, saturated LH₂ is pumped into the dispensing interface via the cryopump, cavitation (i.e., bubbles) occurs, which leads to hydrogen losses. Depending on the quality of the LH₂ being delivered into the cryopump, losses of up to 10% (or more) can occur.

These losses can accumulate quickly. A single hydrogen station dispensing 2000 kg/day with only a 20% loss could result in over US$1 million in lost/vented hydrogen each year, not to mention increased emissions from vented gas.

The solution: zero-loss LH₂ transfer

The next frontier in hydrogen infrastructure is zero-loss LH₂ technology – specifically solutions that prevent boil-off, venting, and other forms of leakage. These systems are not just helpful; they are essential for the economic and environmental viability of hydrogen mobility.

The game changer: LH₂controlled storage

The existing liquid hydrogen value chain as compared to zero-loss, controlled storage.

At the heart of this transformation are active, refrigerated storage systems that can maintain precise temperature and pressure conditions. These systems, often referred to as ‘controlled storage,’ utilize integrated refrigeration of the LH₂, enabling zero-loss cooldowns, offloading, and daily operation.

The key differentiator of controlled storage is its ability to preserve LH₂ and prevent vaporization into GH₂ by actively refrigerating the LH₂. This is much more efficient than the energy-intensive alternative of capturing and reliquefying boil-off gas. Incorporating controlled storage into LH₂ storage infrastructure yields clear advantages.

Benefits of zero-loss LH₂ systems include:

- No venting means no emissions.

- Zero-loss transfilling and tank cooldown.

- Significantly reduced operating costs.

- Higher energy density and infinite storage durations without losses.

- Improved hydrogen refueling station reliability and equipment longevity.

- High throughput refueling with fewer assets.

- Flexibility to fuel both GH₂ and LH₂ onboard tanks.

- Complete control over the state of the hydrogen molecule.

- Energy cost to prevent loss is a fraction of the cost to re-liquefy after the loss has occurred.

The GODU study: proof that controlled storage is essential

The Ground Operations Demonstration Unit for Liquid Hydrogen (GODU LH₂) – an initiative led by NASA’s Advanced Exploration Systems Program and conducted at the Kennedy Space Center – is the gold standard for analyzing and validating the feasibility and performance of controlled storage systems.

The GODU-LH₂ study was a ground-breaking NASA project aimed at transforming how we transfer, store, and manage LH₂ – a key fuel used for space exploration. Traditionally, transferring and storing LH₂ has been costly and inefficient. During the space shuttle program, nearly 50% of the hydrogen was lost due to evaporation and transfer issues during operations. Conducted between 2012 and 2016, the GODU-LH₂ study addressed the issue head-on by introducing advanced cryogenic technology to refrigerate, control, and store hydrogen more effectively, thereby eliminating waste in the process.

One of the most important breakthroughs from NASA’s GODU-LH₂ study was the ability to control the state of LH₂ – a notoriously tricky fuel that is light, energetic, and easily lost to evaporation. By utilizing advanced cooling and insulation technology, the study demonstrated how hydrogen can be stored long-term without losses, even allowing engineers to ‘tune’ its temperature and density for different mission requirements. As researchers noted, they were able to ‘dial in’ any point on the hydrogen phase curve and hold it indefinitely – a remarkable achievement in cryogenic fluid control.

Controlled storage represents a significant advancement for the broader adoption of hydrogen, not just for space exploration, but also for commercial applications such as fuel-cell vehicles, clean energy infrastructure, and backup power. The ability to store hydrogen reliably, efficiently, and with zero loss is precisely what is needed to make it a practical and sustainable part of our energy future.

GODU-LH₂ demonstration goals

- Zero-loss storage and transfer (ZBO).

- Gaseous hydrogen liquefaction in situ.

- LH₂ densification – increasing energy density by cooling below standard boiling point.

Rigorous validation

- Successfully operated across tank fill levels of 33%, 67%, and 100%, demonstrating uninterrupted thermodynamic control at any fill level.

- Maintained temperature, pressure, and mass flow stability over ~19 months of testing.

- Delivered zero boil-off performance as long as refrigeration matched heat ingress, providing clear proof of the controlled storage concept.

The results of the study were very clear: controlled storage is not a nice-to-have, it is mission-critical. Without refrigeration, hydrogen bulk storage tanks experience significant losses during fill and transfer operations. With controlled storage, these tanks can preserve fuel for anywhere from days to indefinitely – even under fuel demand cycling.

A new era in hydrogen mobility

Controlled storage is not just a technological achievement; it is the foundation of a scalable, sustainable, and commercially viable hydrogen future built on proven science and measurable results, and it is not just theoretical. Industry leaders are deploying zero-loss LH₂ systems in the field today. In April 2025, a landmark partnership between Hyroad Energy, Bosch Rexroth, and GenH2 announced plans for the first zero-loss LH₂ refueling station in the US. Station construction is scheduled to begin later this year with operations expected to commence by 2026. Located in Texas, US, this station will demonstrate the technical feasibility and commercial viability of controlled storage while dispensing thousands of kilograms of hydrogen per day.

This achievement signals a pivotal moment for hydrogen mobility. As infrastructure scales from pilot programs to regional networks, the ability to store and distribute LH₂ efficiently, safely, and without loss will determine the success of hydrogen as a mainstream energy alternative.

The GODU study did not just push technology; it changed the paradigm. We now know that an active heat removal process powered by external refrigeration has been proven to prevent boil-off and deliver hydrogen efficiently. Refueling stations built on this model – such as the upcoming Texas installation – will usher in a new era of commercially viable, environmentally responsible hydrogen fueling infrastructure, supporting carbon-neutral freight corridors, municipal fleets, aviation ground support, and backup power systems.

Conclusion: a revolution, not just an upgrade

Zero-loss LH₂ technology is more than an innovation – it represents a technological and commercial shift in how hydrogen can be stored, distributed, and consumed. It eliminates long-standing inefficiencies, reduces infrastructure costs, and enables a more sustainable and scalable energy economy. If hydrogen is to fulfill its promise as the fuel of the future, LH₂ and zero-Loss technologies will be the pillars that support its rise. The path to a clean, net zero world runs through cryogenic precision, innovative engineering, and bold investments in the future of LH₂.

This is a repost from Global Hydrogen Review (pp 45-48).